Finishing Explained

Raw Material

Designer Doorware uses an array of raw materials including brass, stainless steel (304 and 316 Marine Grade), aluminium, steel and zinc. It is very important to prepare raw materials correctly. After machining or forging they must be properly prepared for the finishing process to achieve a high quality result - the better the preparation of the base material, the better the end finish.

Designer Doorware uses an array of raw materials including brass, stainless steel (304 and 316 Marine Grade), aluminium, steel and zinc. It is very important to prepare raw materials correctly. After machining or forging they must be properly prepared for the finishing process to achieve a high quality result - the better the preparation of the base material, the better the end finish.

By using specialised finishing methods, Designer Doorware produces quality products that will not only complete the aesthetic look of any high-end project, but also resist corrosion and lengthen the overall service life of the hardware.

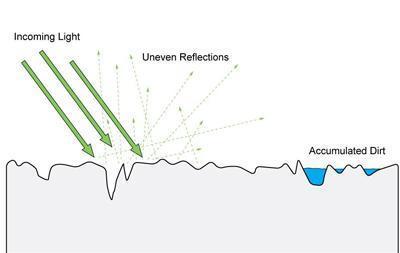

This image shows a magnified cross section of a raw material sample. It contains deep valleys, sharp crests and numerous pits created during the production process.

At Designer Doorware, we finish our products in many ways. Some of these include linishing, polishing, satining and electro-plating or bronzing.

Linishing Process

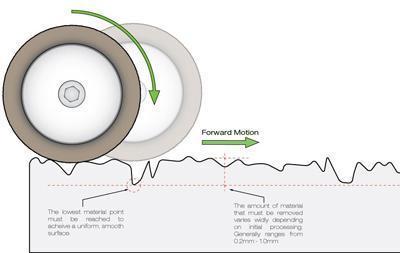

In linishing, the surface is sanded smooth using a linishing belt or abrasive pad until the lowest point of the material is found to achieve a uniform surface. This process can produce a significant amount of waste and remove up to 1mm of material from the surface.

In linishing, the surface is sanded smooth using a linishing belt or abrasive pad until the lowest point of the material is found to achieve a uniform surface. This process can produce a significant amount of waste and remove up to 1mm of material from the surface.

For this reason it is generally discouraged if the part to be finished requires tight tolerances or certain strength. While this method is laborious and time consuming, the finish that can be achieved from finishing raw metal is considered attractive and robust.

Polishing and Final Finishing

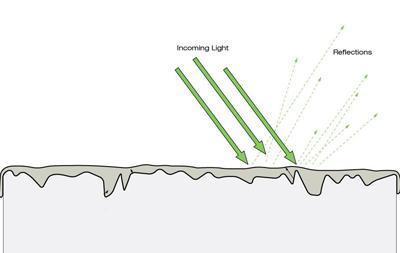

Once the surface is linished, the product is polished and buffed to achieve the correct final surface finish.

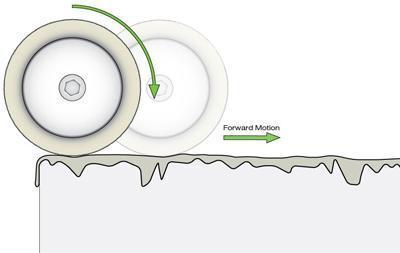

If a gloss finish is required, a buffing wheel is used to reduce the slight imperfections in the surface condition until the case is completely smooth. This process works in much in the same way as linishing with raw metals, however far less material is removed.

If a gloss finish is required, a buffing wheel is used to reduce the slight imperfections in the surface condition until the case is completely smooth. This process works in much in the same way as linishing with raw metals, however far less material is removed.

If a satin, bronze or antique worn finish is required, a similar buffing process is used to create a uniform surface, after which an additional abrasive is used to roughen the material strategically to produce a uniform “grain” or pattern.

In most cases this stage is done by operators working solely by hand and feel. While Designer Doorware takes all care to ensure each finish is consistent across our range and to the highest standard, there is no guarantee each individual product finish will match in either colour or grain.

Plated, Bronze, Antique and Lacquered Finishes

In order to achieve a consistent, attractive finish, the final surface needs to be coated with the appropriate material depending on the desired finish.

One example is brass products which are usually coated by electro-plating. One of the electro-plating finishes often used is chrome (or a chrome alloy) because it is highly versatile and attractive with high resistance to corrosion and impact damage.

In chrome electro-plating, the coating of the material surface is achieved by attaching the negative electrode of a power source to the material to be plated and immersing it in a liquid solution containing positively charged Chromium ions. The Chromium ions are attracted to the negative charge and attach themselves to the surface forming a solid deposit.

In chrome electro-plating, the coating of the material surface is achieved by attaching the negative electrode of a power source to the material to be plated and immersing it in a liquid solution containing positively charged Chromium ions. The Chromium ions are attracted to the negative charge and attach themselves to the surface forming a solid deposit.

Designer Doorware offers an extensive range of high quality special finishes.

For further information, call our friendly, expert consultants on +613 9300 8888 or email us.

No items in archive.

About Designer Doorware's Capabilities

Designer Doorware designs and manufactures superior quality door furniture and architectural hardware including hinges, door handles and door knobs, door pull handles, sliding door hardware, door hardware accessories, door closers, locks, cabinet door handles, and bathroom accessories. Our products offer timeless qualities to suit a variety of architectural styles and budgets, with thousands of product options and combinations to choose from.

If you are looking for something extra special, our custom design service can create hardware to complement any commercial or residential project, no matter how unique your requirements. We regularly work with Architects, Designers, Developers and Builders on award winning projects of all sizes across Australia, Asia-Pacific and the USA. With know-how gained through many years of specialised design experience, a well-established international network and best-of-breed manufacturing capabilities, we can operate to short lead times and quickly deliver doorware and accessories anywhere in the world.

Our new Selector Tool makes it easy to visualise, compare and select architectural hardware online. You can review a wide range of products, find related products, get tailored specification sheets, make them into a PDF book and request a quote for your specified products. We also make doorware selection easier with customer services that incorporate interior design advice, specifying, scheduling and more. Contact our friendly, highly qualified team to help create that final complement to your project.